Is Polyester Really *That* Bad?

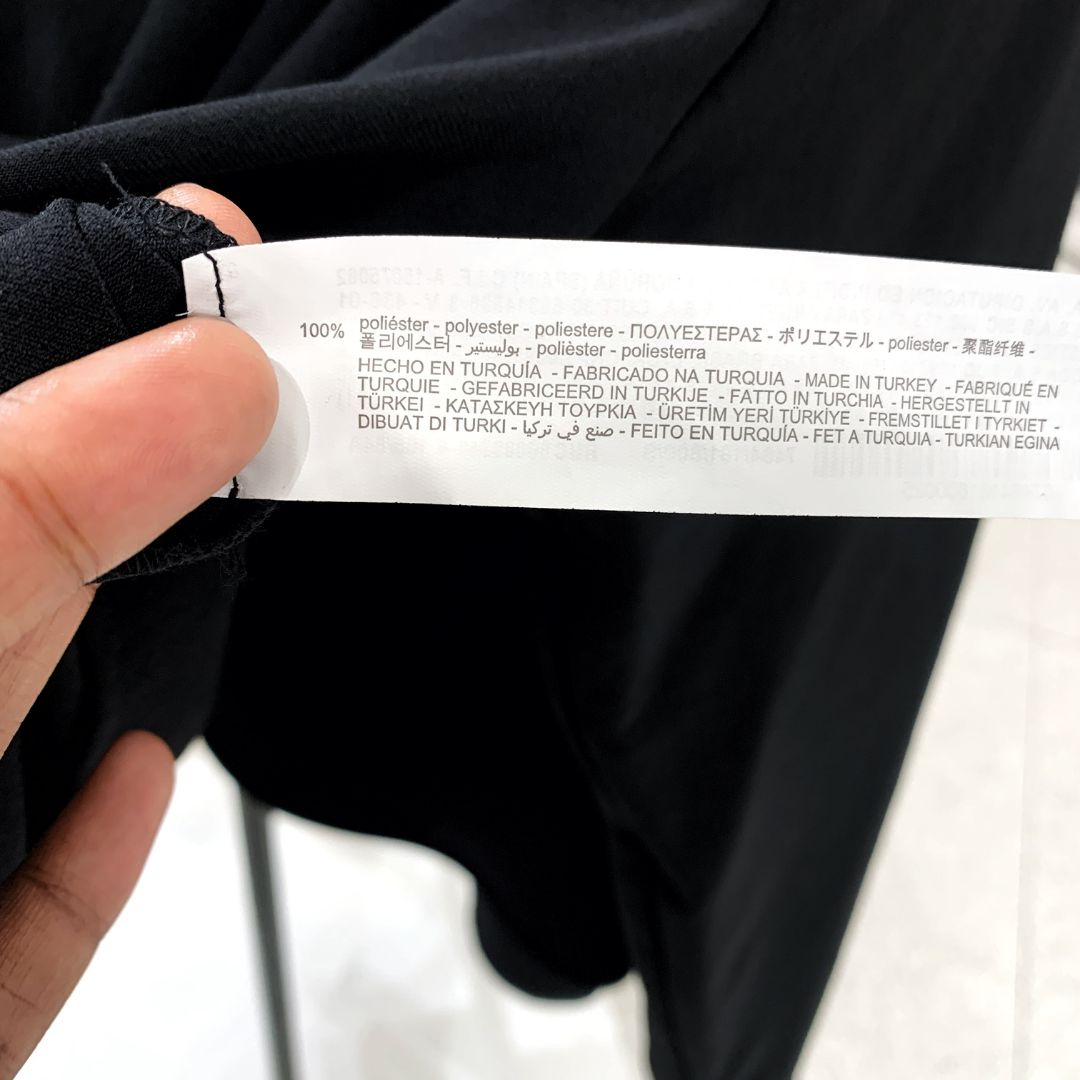

Polyester, technically known as polyethylene terephthalate (PET), is a synthetic woven material derived from petroleum. Yes, oil. Known for being incredibly durable, versatile, and relatively inexpensive to produce, polyester has become the most widely used fiber in the textile industry. — accounting for roughly half of the overall fiber market and around 80% of synthetics fiber. According to industry data, in 2018, polyester constituted 52% of global fiber production, amounting to 55 million metric tons produced annually. In 2020, global polyester fiber production increased to 57.1 metric tons.

Where Did Polyester Come From?

Polyester was invented in 1941 by British chemists John Rex Whinfield and James Tennant Dickson; however, it wasn't until the 1970s that this fiber gained popularity as a cost-effective alternative for clothing, due to its low maintenance, durability, and resistance to wrinkles.

It's surmised that the affordability of polyester played a pivotal role in the rise of fast fashion. The low production costs associated with polyester allowed fast-fashion retailers to mass-produce trendy, disposable clothing without incurring hefty expenses. This, in turn, fostered a culture of throwaway fashion that flourished as polyester became increasingly cheap to produce.

The growth of the fashion industry contributed to enhancements in how polyester was produced and distributed, which, in turn, lowered the costs of producing polyester. This symbiotic relationship between polyester and fast fashion created a feedback loop that fueled the growth of both, reinforcing polyester’s status as a staple material in the industry.

From Crude Oil to Rib-Knit Flared Trousers

The production of polyester begins with the extraction of crude oil from the earth, which is a source of the required raw materials - ethylene glycol and terephthalic acid. These compounds undergo a chemical reaction known as polymerization to form polyethylene terephthalate (PET).

In a molten state, the resultant polymer is then extruded through tiny holes in a spinneret device to form long, thin filaments. Once extruded, these filaments are cooled and solidified. They are then stretched or drawn out to many times their original length, which aligns the polymer chains and improves the strength and tenacity of the fibers.

After stretching, the fibers might be texturized to create a bulkier and more usable fiber. They could be cut into staple fibers, which are short lengths of fiber similar in form to natural fibers like cotton or wool. The fibers, whether in continuous filament or staple form, are then spun into yarn. This yarn can be used alone or blended with other types of fiber to be woven or knitted into fabric.

Finally, the yarn is woven or knitted into fabric, which can then be dyed, printed, and finished according to the desired final product specification.

The Environmental Impact of Polyester

Polyester's affordability and versatile characteristics have made it a staple in the fashion industry, but its environmental cost is substantial. The environmental impact of polyester is multifaceted and significant, largely due to its petroleum-based origins and the processes involved in its production, use, and disposal.

Energy Consumption and Greenhouse Gas Emissions:

The core of polyester production is a chemical reaction known as polymerization, where ethylene glycol and terephthalic acid are combined to create a polyethylene terephthalate (PET) polymer. This reaction requires high temperatures to occur, typically around 280°C to 300°C (536°F to 572°F). The energy needed to achieve these high temperatures is significant and often sourced from burning of fossil fuels like coal, oil, or natural gas. These fuels are combusted to produce heat or generate electricity that powers the heating systems in polyester manufacturing plants.

The combustion of fossil fuels releases carbon dioxide (CO2) and other greenhouse gases into the atmosphere. These gases trap heat and contribute to the warming of the planet, aka climate change. The polyester production process itself might also release additional greenhouse gases, depending on the specific technologies and practices employed.

Water Usage:

The manufacturing of polyester demands a considerable amount of water, particularly for cooling purposes during various stages of the production process. After the high-temperature processes, the material needs to be cooled down. Water is often used as a cooling medium due to its effective heat-absorbing properties. It circulates around the equipment, absorbing the heat and cooling down the machinery and the molten polymer.

The quantity of water required can be substantial, especially in large-scale production facilities. After being used for cooling, this water increases in temperature and needs to be cooled down before it can be reused or discharged, which can require additional water.

The water used in cooling systems can become contaminated with chemicals used in production. If this water is discharged without proper treatment, it can pollute local water bodies, affecting both wildlife and human populations.

Some facilities may have water treatment and recycling systems in place to minimize water usage and pollution. These systems can clean and cool the water so it can be reused within the facility. However, the effectiveness and prevalence of such systems can vary widely across different regions and companies.

Furthermore, polyester production facilities tend to be located in regions where water resources are limited or already stressed due to other industrial activities, agriculture, or residential use. The significant water usage by polyester production facilities can exacerbate local water scarcity issues, impacting both human populations and local ecosystems.

Toxic Dyes and Chemicals:

The dyeing of polyester fabric requires the use of certain chemicals to ensure that the dye adheres to the fibers. Some of these chemicals can be toxic, carcinogenic (cancer-causing), or harmful to human health and the environment. Common chemicals used in synthetic dyeing processes include heavy metals, formaldehyde, and aromatic amines.

Workers in dyeing facilities may be exposed to these hazardous chemicals through inhalation, skin contact, or even ingestion. Long-term exposure to some of these chemicals can lead to serious health problems, including skin disorders, respiratory issues, and in severe cases, cancers and other life-threatening diseases.

Furthermore, individuals wearing garments made from chemically treated synthetic materials like polyester can also be exposed to these toxins over time. As highlighted by Alden Wicker in her book “To Dye For: How Toxic Fashion Is Making Us Sick — and How We Can Fight Back”, the potential risks associated with the chemicals used in synthetic fashion have led to an increase in health issues such as autoimmune diseases, infertility, asthma, and eczema.

The dyeing process can also lead to environmental contamination if the chemicals are discharged into local water systems without proper treatment. This can cause pollution in rivers, lakes, and oceans, affecting aquatic life and potentially entering the food chain. The accumulation of heavy metals and other toxic substances in water bodies can have devastating effects on ecosystems and human communities.

Non-Biodegradability:

Polyester is a type of plastic, and like many plastics, it does not biodegrade, meaning it doesn't break down naturally in the environment. Biodegradation is a process where organic substances are broken down by natural processes, aided by microbial organisms, into simpler, non-toxic compounds like water, carbon dioxide, and compost.

Unlike natural fibers such as cotton or wool, polyester does not undergo this process and can remain in the environment for hundreds of years. This characteristic poses a significant waste management challenge, especially given the mass production and consumption of polyester products.

When polyester garments or other products are discarded, they often end up in landfills or as litter in the natural environment. The presence of polyester waste in the soil can affect soil health by disrupting the soil microbial community. Similarly, if polyester waste finds its way into water bodies, it can affect aquatic life and water quality.

Microplastic Pollution:

While polyester isn't biodegradable, it does, however, shed “microplastics,” especially during washing. Due to their size, these minute particles can easily pass through filtration systems in wastewater treatment plants, subsequently entering natural water bodies.

With every wash, millions of microplastics are released into the wastewater system. Once in rivers and oceans, microplastics become accessible to marine life. Fish and other marine organisms can ingest microplastics directly or indirectly by consuming other organisms that have ingested microplastics. This can lead to the accumulation of microplastics in the bodies of marine organisms and, consequently, in the bodies of humans and other animals higher up the food chain who consume these marine organisms.

If you might think avoiding seafood will protect you from this plastic contamination, not so fast. Microplastics have been found in beer, shellfish, and salt. If that's not terrifying enough, it was found that the average person consumes as many as 1,769 particles of plastic every week just by drinking water – bottled or tap. Gross.

The full impact of microplastics on human health and the environment remains unclear due to the relatively recent recognition of this issue and the complexity of studying microplastic interactions within biological and ecological systems. However, what is clear is that the problem of microplastic pollution is extensive and potentially harmful.

Recycling Challenges:

While polyester recycling holds promise in reducing the environmental footprint, the present-day reality underscores a significant gap that needs addressing. While promising technology and innovations are happening in the textile recycling world, closing the loop by recycling textile fibers back into new textiles is still in its infancy. The current absence of a robust global infrastructure for collecting, sorting, and recycling used polyester garments is a significant barrier to achieving higher recycling rates. This includes a lack of facilities, technologies, and systems necessary to collect and process used polyester items efficiently.

According to the 2017 New Textile Economy report by the Ellen MacArthur Foundation, from the share of clothing that is collected for reuse, less than 1% will be used to make new clothing, revealing a stark reality about the inefficiencies and inadequacies in textile recycling. This low rate can be attributed to both technical challenges and systemic issues within the textile and recycling industries.

Today, virtually all recycled polyester in clothing comes from recycled water bottles rather than recycled garments. This is likely due to the more straightforward process of recycling PET (polyethylene terephthalate) bottles compared to the complexities associated with recycling mixed-material or dyed garments.

Therefore, most polyester (and polyester blends) are either incinerated, releasing carbon dioxide and potentially harmful toxins into the air, contributing to air pollution and climate change, or landfilled. Polyester items do not biodegrade easily and pose long-term environmental harm when landfilled. As polyester slowly breaks down, it releases methane, a potent greenhouse gas, and can leach harmful chemicals into soil and groundwater.

Pioneering a Sustainable Shift in Fashion Industry Practices

Polyester has become a cornerstone of the global fashion industry due to its affordability, versatility, and durability. However, its rise, parallel with the rise of fast fashion, has ushered in significant environmental and social repercussions. This scenario underscores the necessity of a holistic approach encompassing technological innovations, policy regulations, industry practices, and consumer awareness to mitigate its impact and tackle the root cause of these issues—overproduction, overconsumption, and fashion’s reliance on fossil fuels.

The inception of the Fossil Fashion Campaign, spearheaded by organizations like Stand.earth, the Changing Markets Foundation, and the Plastic Soup Foundation, heralds a promising stride towards mitigating the impact. The campaign advocates for a significant reduction in fossil fuel usage in materials, alongside the implementation of mandatory Extended Producer Responsibility (EPR) schemes to foster circularity and transparency within the industry.

Outlined within the campaign are three pivotal calls to action: a fair phase-out of fossil fuel-based materials, a commitment to science-based climate targets, and unwavering support for systemic legislative action. Part of this equitable phase-out is also aimed at achieving a 55% reduction in emissions across the supply chain by 2030.

Yet, the question looms: Is such an ambitious overhaul feasible, especially within the stipulated timeline?

The scale at which man-made fibers like polyester and nylon are produced underscores their potential to meet the demands of a burgeoning global populace. Although natural fibers such as cotton, particularly organic cotton, are often heralded as more environmentally benign, they harbor their own set of challenges. There is a need for continued research and innovation to develop new materials and production methods that are both sustainable and capable of meeting global demand. This includes exploring alternative fibers, improving the efficiency of production processes, and recycling or upcycling existing materials.

Fashion's dependency on polyester and synthetic materials has birthed a nuanced dilemma, necessitating a blend of scientific, economic, and policy-driven strategies for navigation. The path towards a more sustainable fashion industry is riddled with complexities, yet with concerted effort across multiple sectors, a viable and eco-conscious fashion landscape is within reach.